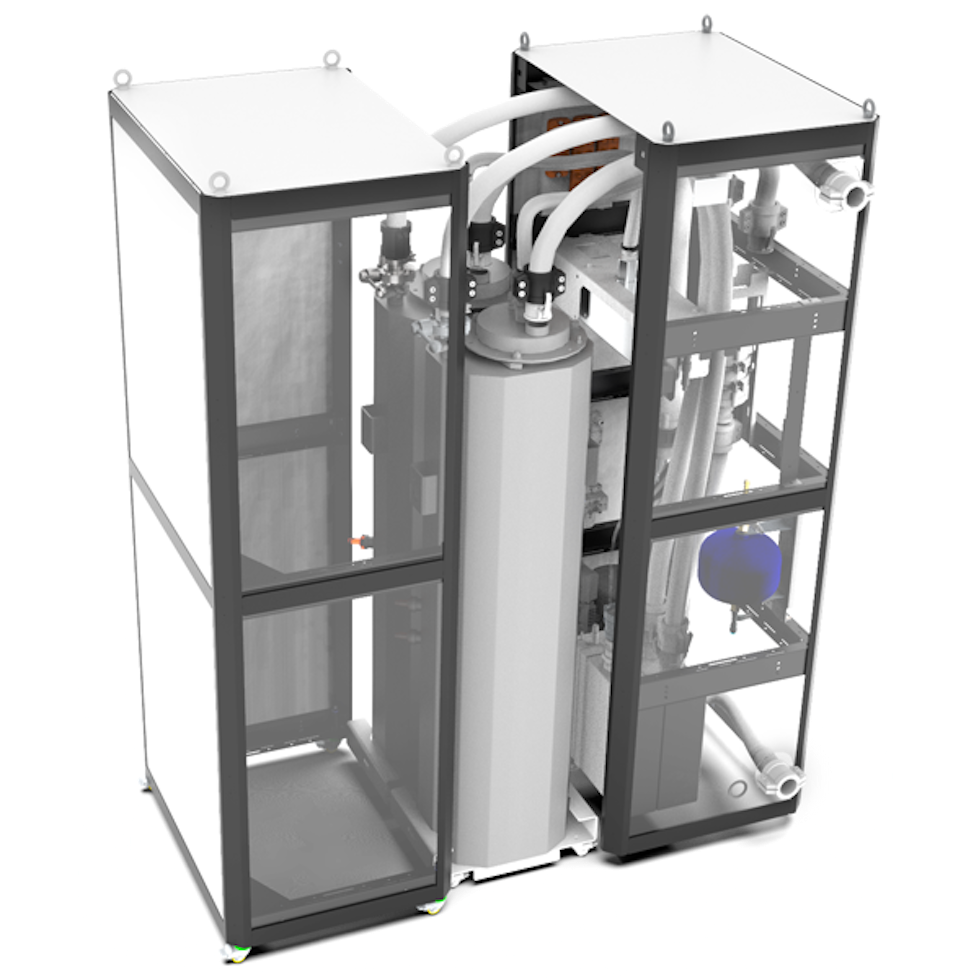

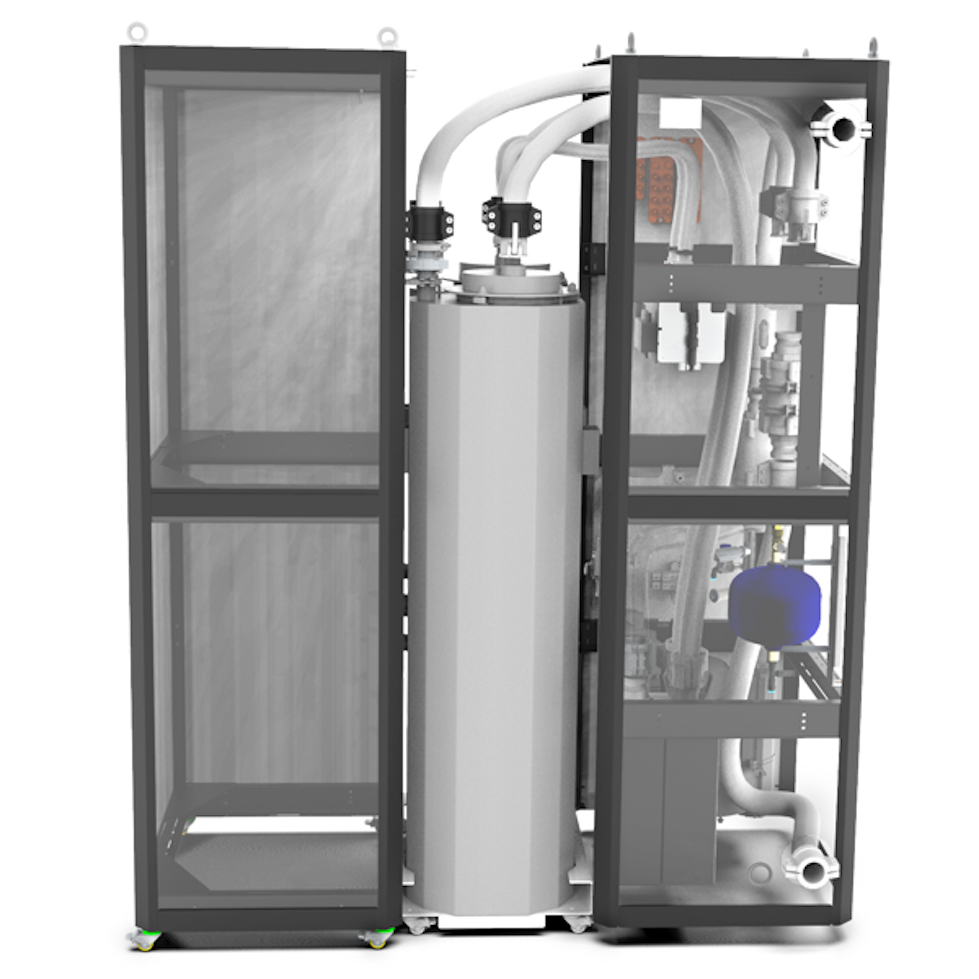

AMF 200 – unique system for process gas cleaning

Product details

Features

Modular, open, and cost-optimized gas cleaning system based to the use of standard components

Contamination-free disposal of the filter elements - high level of safety and containment when removing used filter cells

Scaled systems with several modules allow larger volume flows

Filter cell size optionally selectable according to dust load

Filter cleaning via jet impulse

Simple handling and operation

Technical control operation as a slave with I/O system, or as an independent system run by an individual control

Small footprint

Operation possible with or without dosing of filter aid

Equipment

Frame with housing on castors

Standard: two filter cells, each with 5 m² filter area and dust collection volume up to 60 l

Larger filter cells with 10 m² filter area each possible

Emergency filter utilization for separating coarse dusts

Side channel blower with mounted frequency converter

Various sensors (differential pressure filter stages, fill level filter cell, oxygen, volume flow, temperature)

Shut off process gas inlet, outlet (pinch valves)

Integrated field bus modules

Technical specifications

| Device version | AMF 200 |

|---|---|

| Max. flow rate in m³/h | 200 |

| Max. flow rate in cfm | 118 |

| Max. vacuum in Pa | 10500 |

| Max. vacuum in inch wc | 42 |

| Nominal capacity in m³/h@Pa | 200 @ 13000 |

| Nominal capacity in cfm@inch wc | 118 @ 52 |

| Dimensions in mm (WxDxH) | 800x1200x2000 |

| Dimensions in inch (WxDxH) | 32x8x79 |

| Weight in kg | 240 |

| Weight in lbs | 530 |

| Noise level in dB | 70 |

| Connection variants – diameter in mm | mutable |

| Connection variants – diameter in inch | mutable |

AMF 200 benefits

Quiet operation

ULT’s extraction and filtration systems are especially quiet. This is appreciated by numerous clients worldwide. This means your employees won’t be bothered by unnecessary noise.

High flexibility

Many of the ULT fume extraction systems can be utilized flexibly. For example, you can choose between mobile or stationary systems, device integrations or special ventilation solutions. If necessary, the ideal application is configured by ULT experts on-site.

Easy servicing

ULT’s extraction and filtration systems are designed so that they can be put into operation without problems and easily used. Should there be any questions, our service technicians would be happy to assist you at any time.

Low energy requirements

ULT’s extraction systems reduce the operation and maintenance costs based on your optimal filtration plan. In addition, the system is designed so that the required energy consumption is kept very low.

Optimal filter technology

Using the most sensible filtration technology ensures a long filter service life and, consequently, reduces the costs of maintenance and spare parts. ULT always offers you the optimal solution for your special contaminant technology to achieve the best filtration possible.

Individual extraction solutions

Your extraction systems are adapted to your needs. Starting from the contaminant situation, via your internal processes, to the best possible collection solution, ULT advises and supports you in the selection and installation of your optimal extraction and filtration solution.

Images

We're happy to help you!

We are happy to offer you further information about our extraction systems and the respective filtration technology. We can also configure your individual solution as requested or required.