Extraction systems for odors, vapors, and gases

Control of emissions such as vapors, odors, and gases

Controlling emissions such as vapors, odors, and gases is crucial due to their potential unpleasantness and toxicity. Compounds like adhesive vapors, paint spray, and solvent fumes, which are organic hydrocarbons, can be harmful rather than innocuous.

These emissions can act as respiratory toxins and allergens, leading to respiratory illnesses, eye irritation, or even brain damage within a short time.

Our ACD device series provides comprehensive solutions for extraction devices and filtration technology designed specifically for odors, gases, and vapors. Our specialized equipment meets the necessary regulations for protecting against explosions or aggressive environments.

We offer a range of options, including direct workplace extraction in both mobile and stationary variants, as well as integrative or complete solutions for the entire workplace.

Filtration systems for vapors, odors, and gases

The mobile solution for emission removal

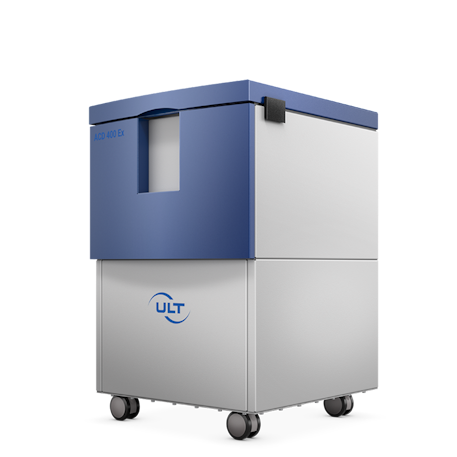

JUMBO Filtertrolley ACD

The JUMBO Filtertrolley ACD is a uniquely designed flexible extraction solution. The mobile systems for filtration of gases and vapors, and odor control can be variably adapted to a wide variety of workplace and pollutant conditions.

The mobile extractor runs extremely quiet and yet powerful.

Importance of extraction and filtration systems

Key considerations for extraction and filtration systems

Discover the essential requirements for an extraction and filter system, including low maintenance costs, health protection, and high work quality. Learn about effective filtration and workplace adaptation for optimal performance.

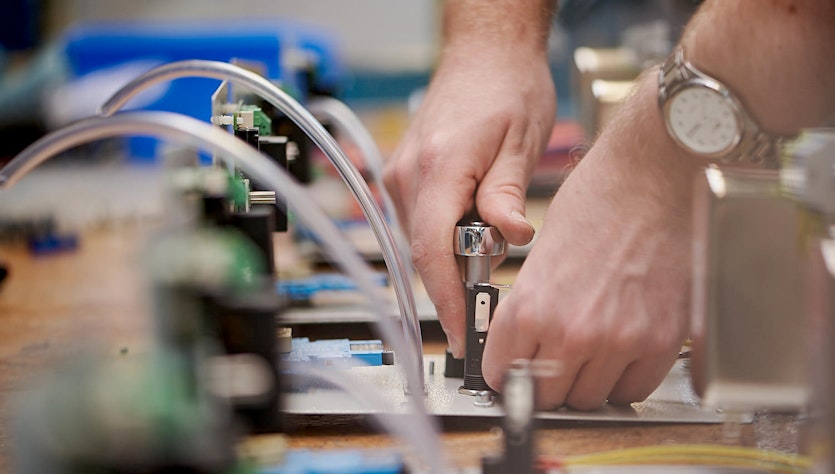

When it comes to extraction and filter systems, several factors play a crucial role. Understanding their importance can help ensure low maintenance costs, protect health, and maintain high work quality. Here are the requirements for an efficient extraction system:

Comprehensive capture: The system should effectively capture all dust, fumes, vapors, gases, or odors produced in the workplace.

Proper filter capacity: The extraction system must be capable of gathering all particles, vapors, and gases generated. Adjusting the filter media capacity according to the quantity of particles is crucial. For instance, when dealing with a high degree of large dust particles, a filter with a high capacity should be used to avoid frequent replacements. Using a filter with low saturation rate can result in higher maintenance costs. Furthermore, increased fine dust concentration may require a reduction in the capacity of a large filter.

Workplace adaptation: Whether used in work halls or as a mobile solution for manual workstations, the extraction and filter technology should seamlessly integrate into the environment. It should operate quietly and non-disruptively while ensuring optimal performance in capture and filtration.

The extraction system must gather all particles, vapors, and gases produced. To that end, the filter media capacity should be adjusted to the quantity of particles present in the filter size. When a high degree large dust particles is produced, a filter with an appropriately high capacity should be used to prevent overly frequent replacements. A filter with too low of a saturation rate can lead to higher maintenance costs. A large filter’s capacity can be reduced in the event of increased fine dust concentration.

Adaptation for the workplace: In either work hall extraction or mobile use in manual workstations, extraction and filter technology should never feel disruptive. It should operate without getting in the way or making significant sound while still guaranteeing high performance in capture and filtration.

By considering these factors, you can select an extraction and filteration system that meets your requirements for low maintenance costs, health protection, and high work quality

Our extraction and filtration systems are specifically designed to control odors, gases, and vapors. With a wide range of turnkey solutions, we can offer you an extraction system that effectively addresses airborne contaminants and is perfectly adapted to meet your requirements.

We're happy to help you!

We are happy to offer you further information about our extraction systems and the respective filtration technology. We can also configure your individual solution as requested or required.