Extraction systems for laser fumes and laser dust

Extraction systems for laser fumes and laser dust

Discover the clear difference with ULT

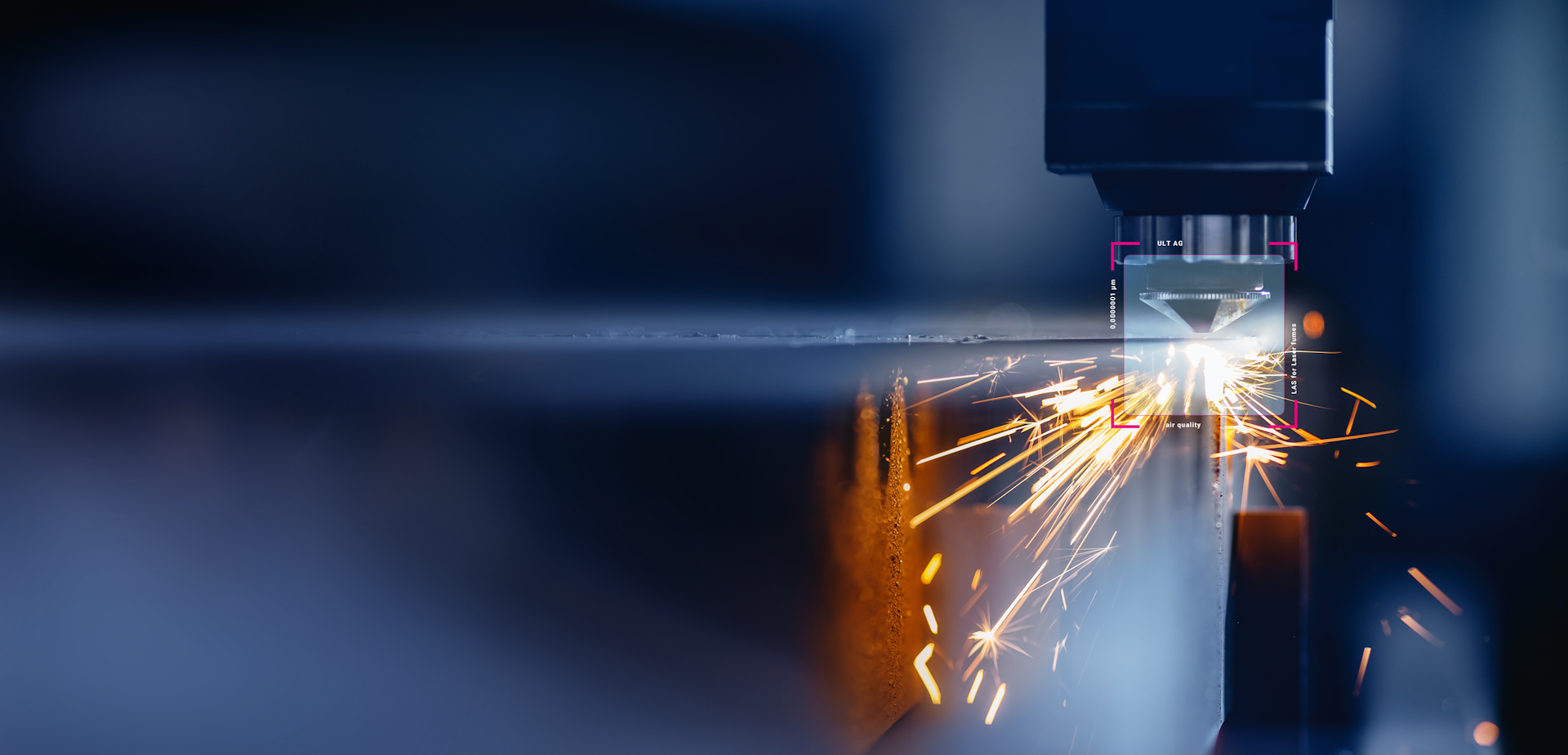

In the dynamic world of industrial innovation, where lasers precisely cut, engrave, weld, and etch, the quality of the air in your workspace significantly impacts your success. ULT’s comprehensive fume extraction solutions are engineered to ensure that your operations are not just compliant but also clean, efficient, and safe.

Clean air, clear advantage.

Why can't you ignore laser fumes?

Laser fumes, filled with particulates and volatile organic compounds (VOCs), are not just an inconvenience; they're a major workplace hazard. These airborne adversaries pose significant health risks and can degrade your valuable machinery over time. Recognizing the seriousness of these fumes is the first step toward transforming your workspace into a productivity powerhouse with ULT's laser fume extractors.

Explore ULT solutions and laser applications!

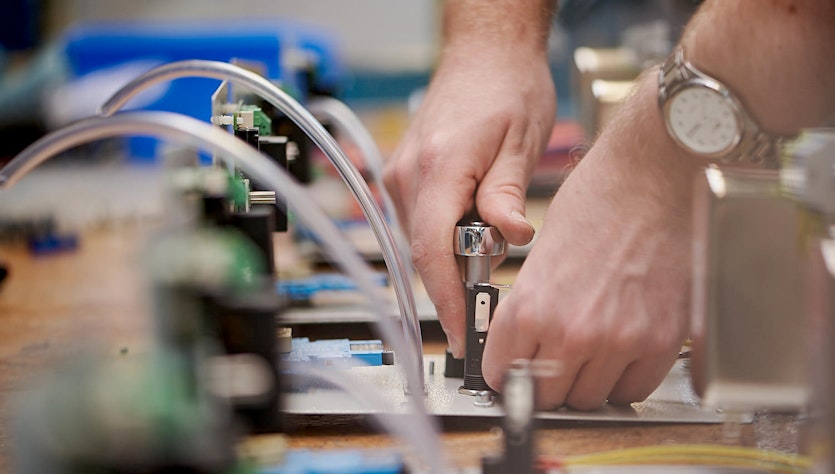

Clean working environment and efficient production

The LAS 260.1 laser fume extractor is currently the most innovative solution for laser fume removal. It is a flexible and mobile system that can be used for a multitude of laser processes on a variety of materials. Whether you are working with metal, plastic, or wood, the LAS 260.1 ensures reliable extraction and filtration of particles and gases/odors from your process.

This means that you can be sure that your working environment and facilities will always remain clean and safe. You can also be confident that your production will be efficient and stable.

Device overview storage filter systems

Device overview cleanable filter systems

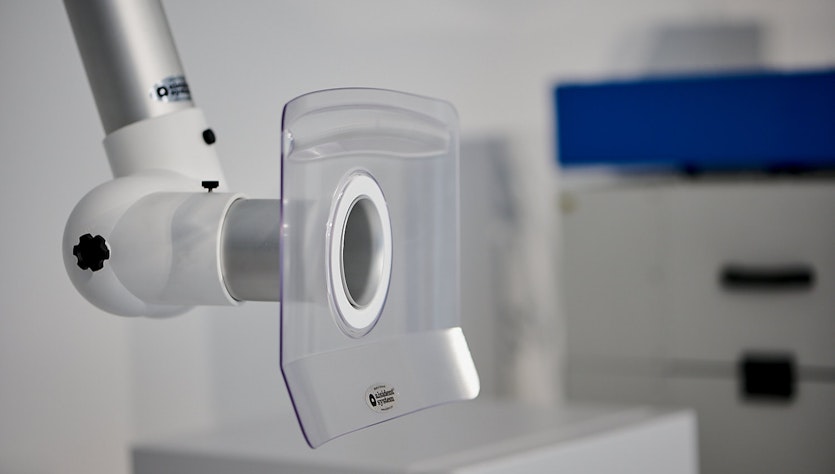

The flexible solution for mobile laser fume extraction

Experience the flexibility of the JUMBO Filtertrolley LAS, a one-of-a-kind unit specifically designed for mobile laser fume extraction. With its attractive design, this mobile extraction system for laser fume and dust can be easily adapted to suit various workplace and emission conditions, providing unparalleled versatility.

Despite its whisper-quiet operation, the JUMBO Filtertrolley LAS boasts impressive power, ensuring efficient extraction performance.

Recommended fume extractors for Keyence and Universal laser systems

The ULT edge

Why choose our laser fume extractors?

The utilization of lasers in various applications such as metal processing, plastic treatment, and organic material manipulation, including laser welding, laser cutting, laser engraving, laser sintering, and additive manufacturing, has become increasingly widespread. However, it is crucial to recognize that laser fumes can pose serious risks.

During metalworking processes, dust containing heavy metals can be generated and subsequently accumulate in the human body. Alloyed metal production releases substances like nickel, chrome, and cobalt. Organic materials undergo pyrolysis, resulting in the formation of highly toxic substances such as dioxin or hydrogen chloride. Additionally, laser fumes contain fine dust particles, which, in the worst-case scenario, can lead to respiratory diseases, cardiovascular issues, and an increased risk of cancer.

Precision purification for every need

What makes a laser fume extractor from ULT essential for your operation?

ULT stands at the forefront of fume extraction technology, offering a suite of solutions that ensure not just compliance but a revolution in air purity. Our laser fume extraction systems, equipped with multi-stage filtration including HEPA filters and activated carbon, are designed to tackle everything from microscopic particulates to hazardous gases.

Whether you're involved in laser cutting, laser engraving, laser cleaning, or laser marking, ULT has a tailored laser fume extraction solution that fits seamlessly into your operations, enhancing safety and efficiency.

Advanced filtration technology: our high-efficiency systems capture and neutralize a broad spectrum of pollutants, from dust particles to gaseous contaminants.

Customized solutions: from compact units for small workshops to industrial-grade systems for large-scale operations, we offer a range of laser fume extraction products designed for your specific needs.

Reliable performance: our filtration technology is built to last, minimizing downtime and maintenance costs, optimize the airflow, ensuring your operations run smoothly day in, day out.

Compliance and beyond: meet and exceed health and safety standards, including OSHA regulations, protecting your workforce and avoiding costly fines.

We're happy to help you!

We are happy to offer you further information about our extraction systems and the respective filtration technology. We can also configure your individual solution as requested or required.

Extraction of laser fumes during material processing

If you utilize laser systems for processes such as laser marking, laser cutting, laser welding, laser deposition welding, laser structuring, laser cleaning, laser ablation, or additive manufacturing, we have the ideal solution for you. Are you in need of an extraction system that meets your specific application requirements?

Our LAS series comprehensively addresses the extraction and filtration needs for laser fumes and laser dust across various industries and applications. Whether it's for laser systems in any field, we have you covered with our complete range of extraction systems and filtration technologies.

Implementing your ULT laser fume extraction solution

Seamless integration, superior support, cland and safe.

Ready to elevate your air quality? Integrating a ULT laser fume extraction and filtration system into your operations is a straightforward process that pays dividends in air quality and operational efficiency. Begin with a consultation with our experts, who will assess your needs and recommend the perfect laser fume extraction solution. Installation is quick, ensuring minimal disruption to your workflow. Plus, with ULT's unmatched support, you’re covered for the long haul, from maintenance tips to troubleshooting.

Laser fume: carrier of hazardous materials

The utilization of lasers in various applications such as metal processing, plastic treatment, and organic material manipulation, including laser welding, laser cutting, laser engraving, laser sintering, and additive manufacturing, has become increasingly widespread. However, it is crucial to recognize that laser fumes can pose serious risks.

During metalworking processes, dust containing heavy metals can be generated and subsequently accumulate in the human body. Alloyed metal production releases substances like nickel, chrome, and cobalt. Organic materials undergo pyrolysis, resulting in the formation of highly toxic substances such as dioxin or hydrogen chloride. Additionally, laser fumes contain fine dust particles, which, in the worst-case scenario, can lead to respiratory diseases, cardiovascular issues, and an increased risk of cancer.

Furthermore, apart from the detrimental impact on the quality of work due to persistent smoke and odors, machine damage can occur due to the presence of pollutants and chemical reactions with products. In precision industries like fine mechanical work, where accuracy is measured in micrometers, any interference from particles must be prevented.

Airborne pollutants, regardless of their size, have repercussions on individuals, machines, and products. In addition to health concerns, prolonged employee absences due to illness can have economic implications for businesses, just as machines that become dirty may lose their operational precision. Maintenance, post-production efforts, and the subsequent loss of reputation, as well as a decline in customer inquiries, are just a few of the negative impacts that can arise.

Frequently Asked Questions

How do ULT extractors tackle such a wide range of contaminants?

ULT’s multi-stage filtration process, combining physical and chemical methods, is designed to capture and neutralize a broad spectrum of contaminants, ensuring that the air in your workspace is not just compliant but truly clean. From particulates as small as 0.3 microns to a wide variety of gases and VOCs, our laser fume extractors ensure your air is purified.

Absolutely. ULT offers a comprehensive range of solutions, from solutions for smaller spaces to heavy-duty systems for large-scale industrial environments. Each laser fume extractor can be tailored to meet the specific demands of your operations, ensuring efficient and effective fume extraction regardless of the size or scale of your projects.

Health and efficiency: ULT’s laser fume extractors safeguard your team's health and boost your operation's efficiency.

Advanced filtration: with HEPA and activated carbon filters, our systems tackle a wide range of pollutants.

Tailored solutions: find the perfect fit for your needs, regardless of your industry's scale or specificity.

Unrivaled support: From consultation to installation and beyond, ULT is with you every step of the way.