Our presence for air handling systems

For closest proximity to our customers

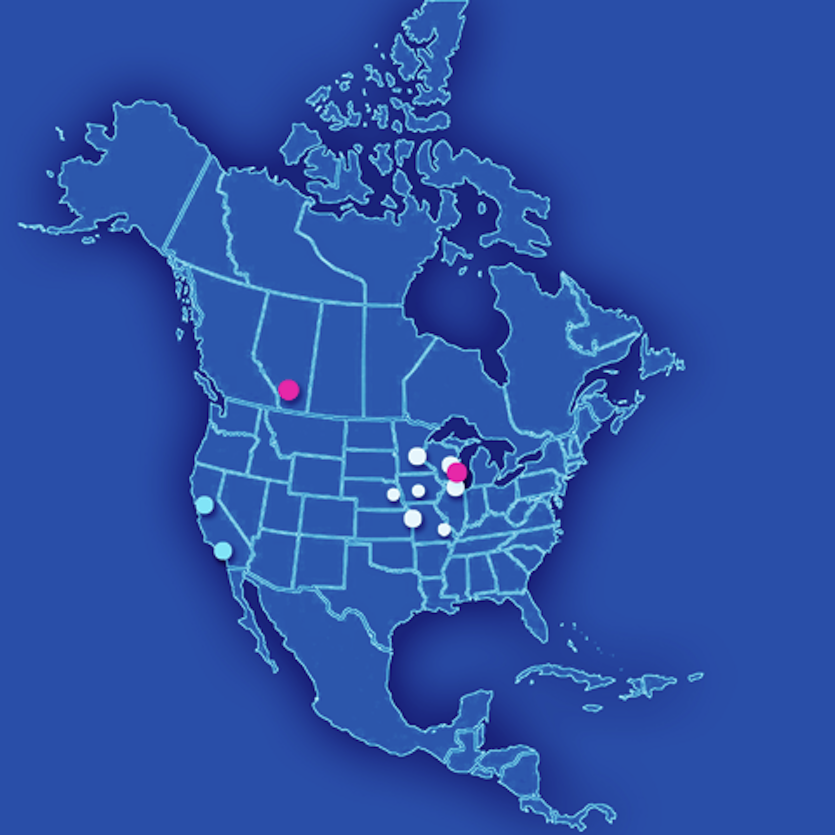

ULT is active in North America, serving the whole continent.

Our subsidiaries and our sales and service partners cover customer support in the USA, Canada and Mexico.

North American presences

Contact us or our representatives

Pink buttons: ULT presences in Okotoks, AB/CAN and Mequon, Wi/USA

Cyan buttons: ACT - Air Cleaning Technology (rep)

White buttons: Gladwin Machinery & Supply Co. (rep)

.

.

Would you like to be part of an expanding network? Are you interested in successfully growing with us? There are many potential customers for fume extraction technology in North America.

So, don't hesitate to contact us! We're looking forward to your message.

We're happy to help you!

We are happy to offer you further information about our extraction systems and the respective filtration technology. We can also configure your individual solution as requested or required.

Global presence ULT

ULT is a globally active company, serving customers and trade partners all over the world.

Find more information on our international presences providing sales and service.